Berry Innovative Digital Labelling

Two recent innovative projects have showcased how, through digital labelling, one scan can offer infinite possibilities for berry products.

Streamlining Cross Border Trade through Digital Labelling

Cross Border Trade Challenges for Fresh Produce

Australia’s domestic food supply relies on fresh produce moving across state borders. Quarantine inspections prevent the spread of crop diseases from affected, to unaffected areas. At inspection, consignments must demonstrate compliance with biosecurity procedures, but this documentation is often paper based. Lost or incorrect paperwork can result in inspection failure and trade losses for producers and customers.

Digital Labelling Solutions for Biosecurity Documents

The Australian Government’s Department of Agriculture, Fisheries and Forestry (DAFF) funded a trial under its RegTech Research and Insights grant program. This project piloted the use of digital biosecurity documents, accessed through digital labelling on fresh produce. Digital labelling could be scanned by quarantine inspectors using simple and effective digital tools , thereby eliminating paperwork.

Real-time Testing of Raspberry Consignments Across State Borders

FreshChain Systems, an Australian Digital Traceability and Provenance solution provider, led a multi-party consortium including Costa Group, who produce Driscoll raspberries. They collaborated with quarantine teams from the New South Wales Department of Primary Industries (NSW DPI) and the Western Australia Department of Primary Industries and Regional Development (WA DPIRD). The trial explored how digital tools and labelling could make inspections more efficient for a raspberry shipment travelling from Costa Group’s NSW production site to WA Farm Direct’s import site.

Digital Labelling with GS1 Standards

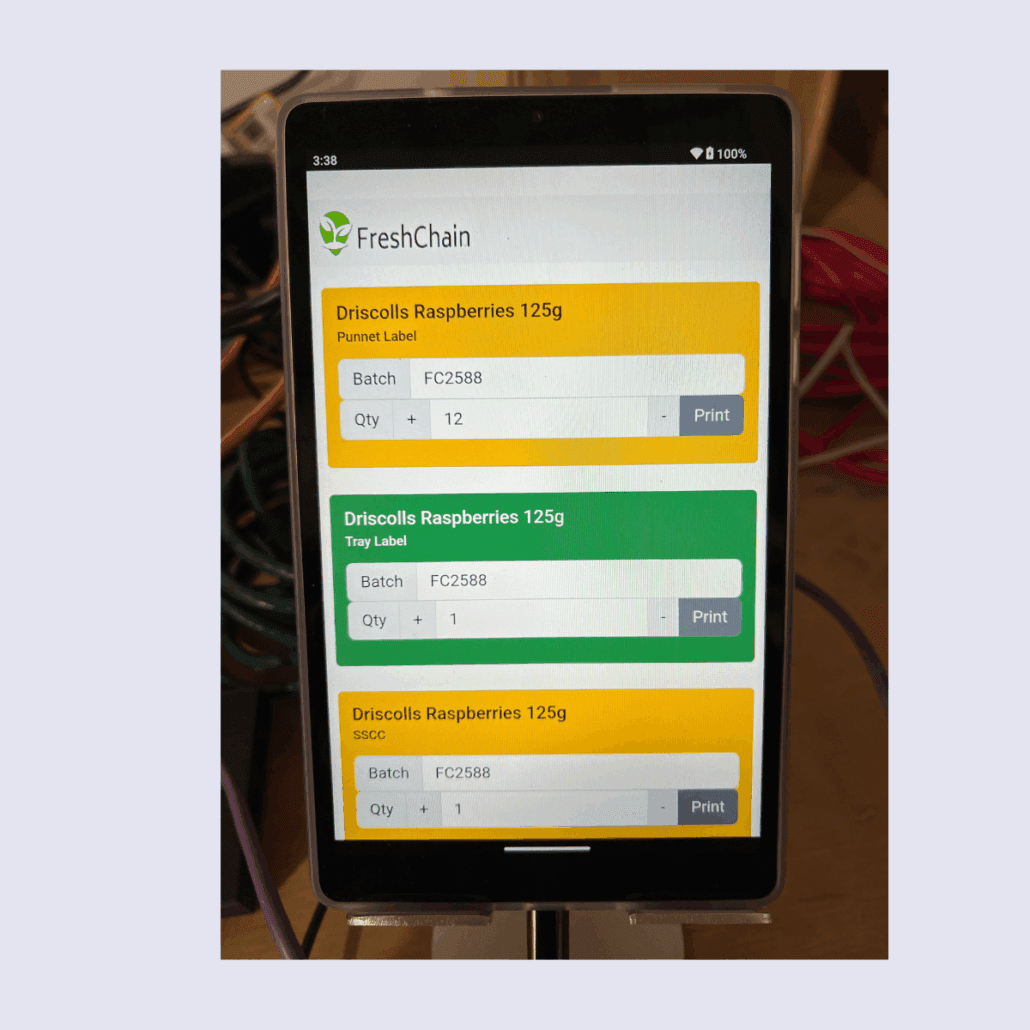

The raspberry consignment was digitally labelled with GS1 powered QR Codes, associated with the following GS1 standards:

- SGTINs (Serialised Global Trade Item Numbers) on punnets linked to

- SGTINs (Serialised Global Trade Item Numbers) on crates linked to

- SSCCs (Serial Shipping Container Codes) on crates

Digital Labelling Linkages

The GS1 powered QR Codes were digitally linked to the:

- Purchase order for the truck driver

- Biosecurity documentation: Phytosanitary declarations

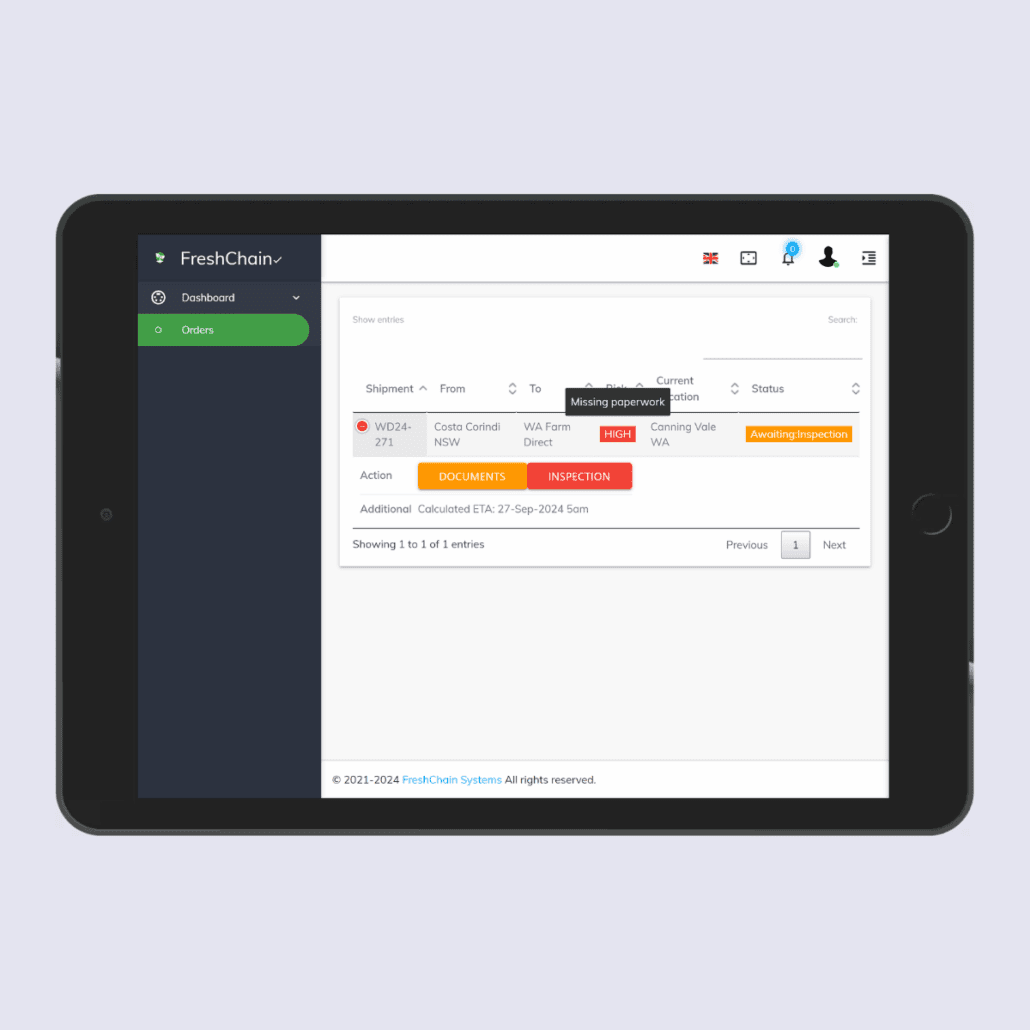

Example of notification of missing paperwork on the FreshChain dashboard

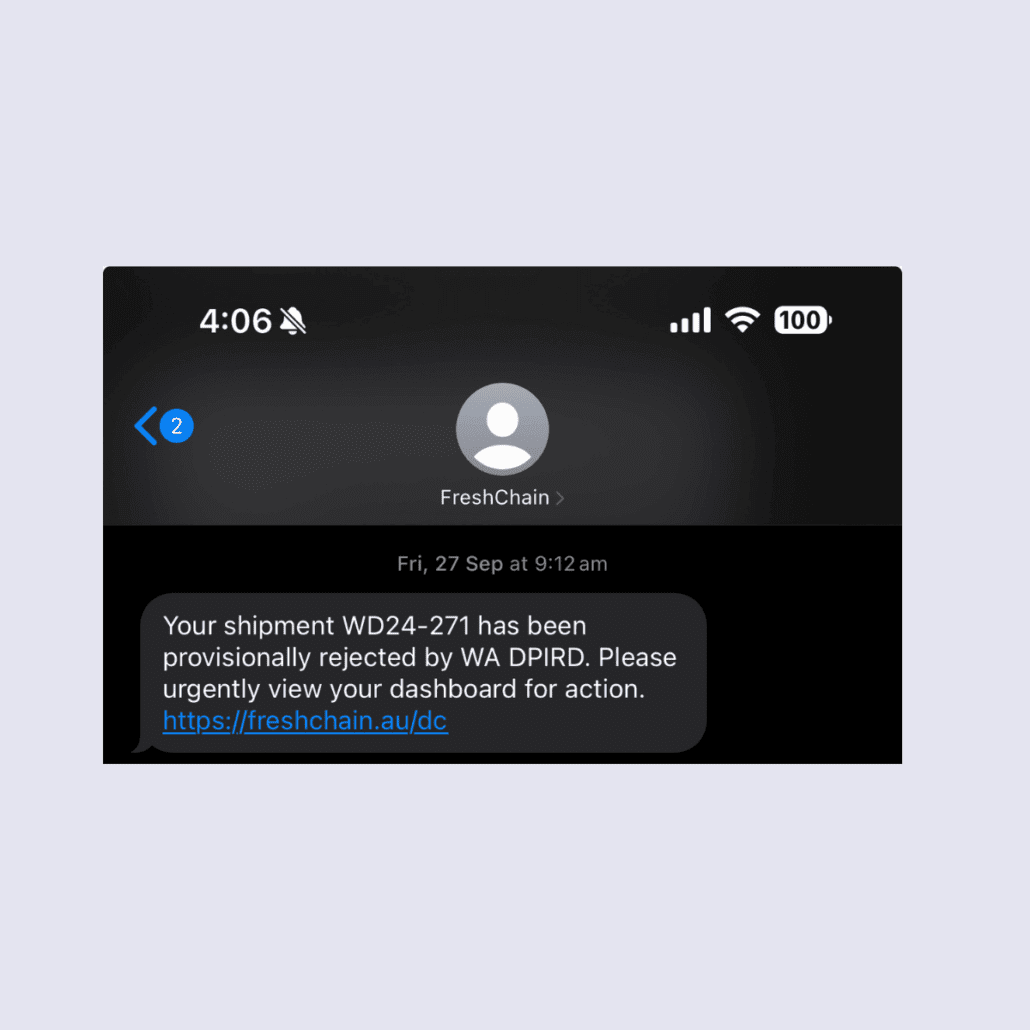

Example of a rejection alert, prompting the supplier to remediate

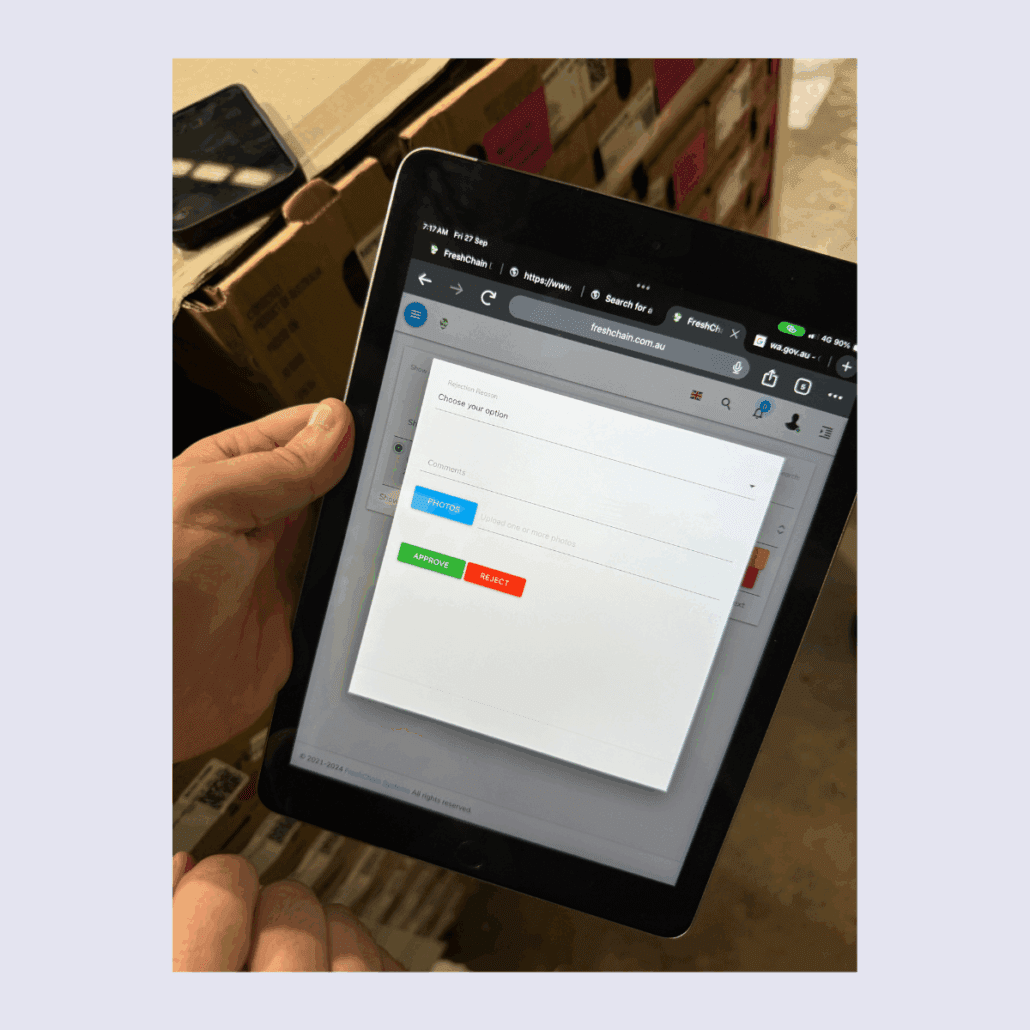

Image of an inspection

Traceability data available on punnets, trays and pallets, accessed via GS1 powered QR codes

Digital Labelling: A Preventative and Remedial Solution

FreshChain developed both preventative and remedial digital tools for this trial to reduce the likelihood of rejections through missing or incorrect paperwork and biosecurity documentation. During the project, the following scenarios were successfully tested:

Preventative: Digital tools with AI capability trialed in the pack shed to ensure that no consignment leaves the producer’s site without the correct biosecurity documentation.

Remedial: Using the newly developed tools, WA quarantine inspectors trialled scanning linked GS1 labels to access biosecurity documentation. If a certificate was missing or incorrect, the inspector could trigger an automatic alert to the producer and other supply chain parties, notifying them of a protocol breach. The exporter then had 30 minutes to upload the correct or missing digital documentation remotely, with a full audit trail captured for future reference. Once updated, the inspector could rescan the label to verify compliance, allowing the consignment to pass inspection and cross the border.

“ As we regularly move our berries interstate, missing paperwork has often caused frustrating delays. Implementing digital traceability through FreshChain has the potential to transform our operations.”

Tanya Gridley National Compliance & Sustainability Manager – Driscoll’s

Shaping the Future of Cross Border Trade

This project shows how scannable digital labelling can streamline cross border trade by linking to accurate digital biosecurity documentation. Marking the first step toward a digital passport for agricultural products, boosting productivity, reducing food waste from failed consignments, and strengthening biosecurity for producers. The ultimate goal is a National “Green Pass” for horticulture, enabling inspection resources to focus on high risk consignments and allowing compliant loads to move efficiently without compromising biosecurity protocols.

“ Digitalising and sharing compliance paperwork in real time represents a major advancement in strengthening food safety, biosecurity, and market access. This pilot stands as a landmark achievement for the sector.“

Dr Sukhvinder Pal (SP) Singh, an expert in food safety and traceability at the NSW Department of Primary Industries and Regional Development

Enhancing Food Safety, Quality and Consumer Engagement through Digital Labelling

A Snapshot of the Victorian Strawberry Industry

The Victorian Strawberry Growers’ Association (VGSA) represents 85 farms that produce over 23,000 tonnes of strawberries annually, accounting for 36% of the national supply.. Most strawberries are consumed domestically, with limited exports mainly to Southeast Asia and Europe. While domestic demand remains strong, the industry is focused on creating new demand through national and state marketing campaigns, developing and testing international varieties, addressing labour shortages, and meeting future regulatory requirements. Technological advancements such as digital labelling offer solutions to help meet these challenges.

Technological Advancement through Digital Labelling

To drive technological advancement for their industry, the VGSA, with funding from Agrifutures, partnered with AusBerry Farmers to trial digital labelling. AusBerry Farmers are a cooperative of 14 family strawberry farms operating predominantly from the Yarra Valley in Victoria.

The project team worked with FreshChain Systems, an IT solution provider, to implement digital labelling to successfully address three challenges:

- Food Safety: Linkage to food safety certification

- Quality: Analysis of fruit quality metrics based on consumer feedback

- Consumer Engagement: Showcasing of the farm, region and growing practices through digital marketing

Scalable Digital Labelling with GS1 Standards

Across two AusBerry farms, 200,000 punnets were digitally labelled with GS1 powered QR Codes. A simple scalable solution was implemented:

- SGTINs (Serialised Global Trade Item Numbers) were applied to punnets in a pre-production phase

- Punnets were distributed to the 2 farms randomly

- Punnet SGTINs were activated on each farm, by activation scanning at the time of fruit packing, by scanners mounted on the packing lines

- Punnet SGTINs thereby became linked to the correct individual farms within the traceability software platform

In summary, this easy to implement solution enabled any punnet to go to any farm, with scanning and activation taking place on each farm, enabling easy scalability.

Strawberry Packing Line

Punnet with GS1 Powered QR Code

Information available via scanning the GS1 powered QR code

QR code with GS1 digital link displayed on the berry punnet

Multiple Benefits of Digital Labelling

Through scanning the GS1 powered QR Codes with their smartphones, supply chain partners and consumers were able to:

- Food Safety: Access certifications such as HARPS and Freshcare

- Quality: Provide punnet specific through each SGTIN, enabling producers to compare and contrast quality metrics between farms

- Consumer Engagement: Customers scan the codes to watch farm videos, explore recipes and see harvest location details.

(Engagement results: farm videos 99%, recipes 22%, harvest location 13%)

Finally, the project used AI analytics to convert item-level feedback and engagement into actionable insights for growers and brand owners.

A Scalable Solution for Horticulture

This project demonstrates a simple, scalable technology solution for horticulture. Through digital labelling, one scan can offer infinite possibilities for berry products; food safety, quality and consumer engagement are the first opportunities of many.

“Setting up the traceability system was easy. It took just a few hours to install the scanner and some small tweaks to the label to add the QR code. Once it was set up it scanned every punnet automatically – we never had to touch it. If we were to do it again we’d add even more internal metrics, like pack date and cold chain handling, and place the QR code more prominently so consumers could see our marketing information even more clearly.”

Dominic Spirli, AusBerry Grower

“Digital traceability tools shouldn’t have to be complicated or expensive. The goal of this project was to develop a scalable, flexible, easy-to-deploy traceability system that’s accessible to farms of every size. This pilot demonstrated that it’s possible to leverage digital traceability technology to track berries from field to customer, capture useful quality metrics, and engage directly with consumers in a cost-effective way, regardless of farm scale.”

Victorian Strawberry Growers’ Association